Well I put some paint on 1 side of the boat.........

Damn!!! That will be a fast trimaran when you add the pontoons and rig to it. ![]()

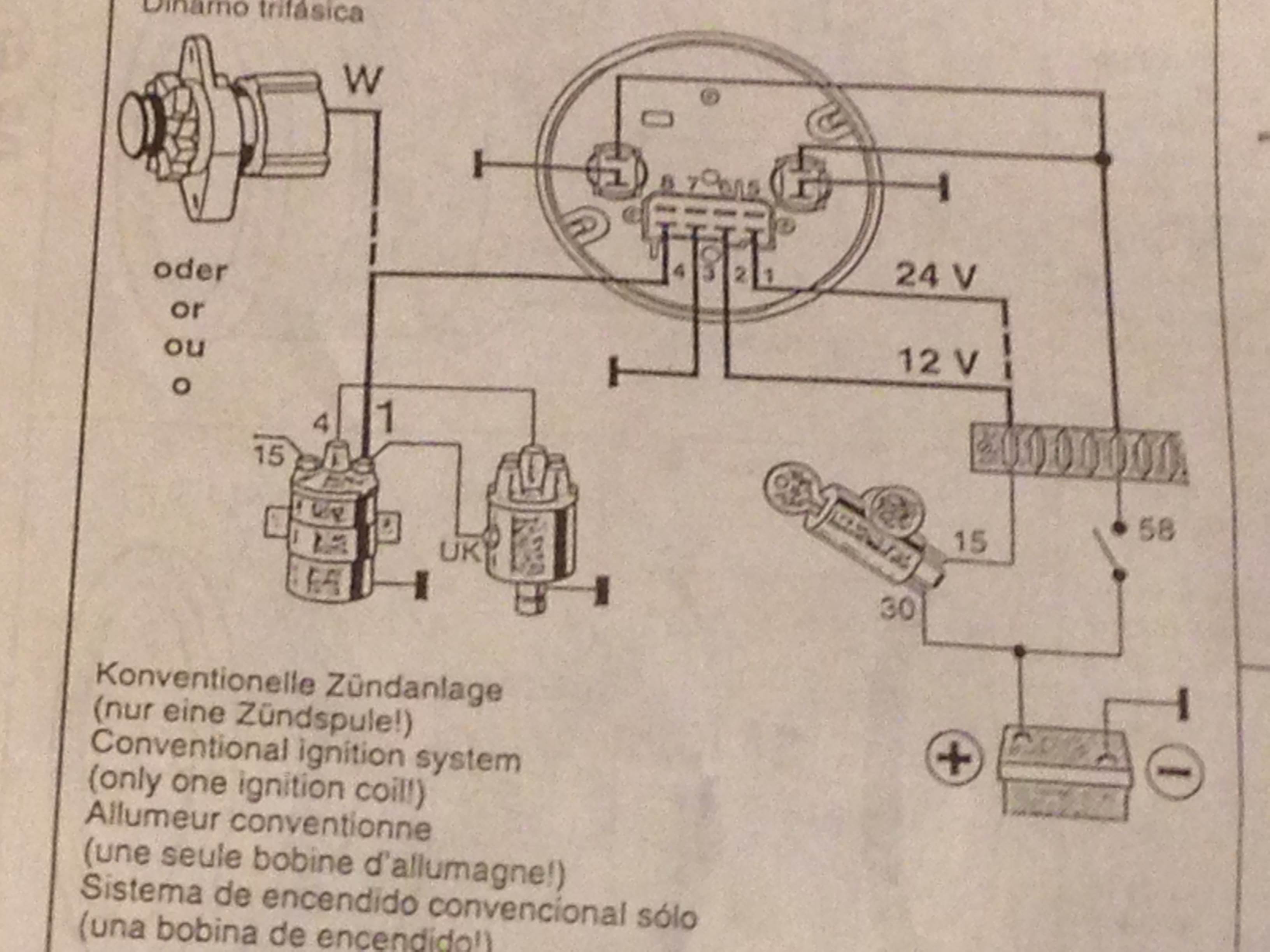

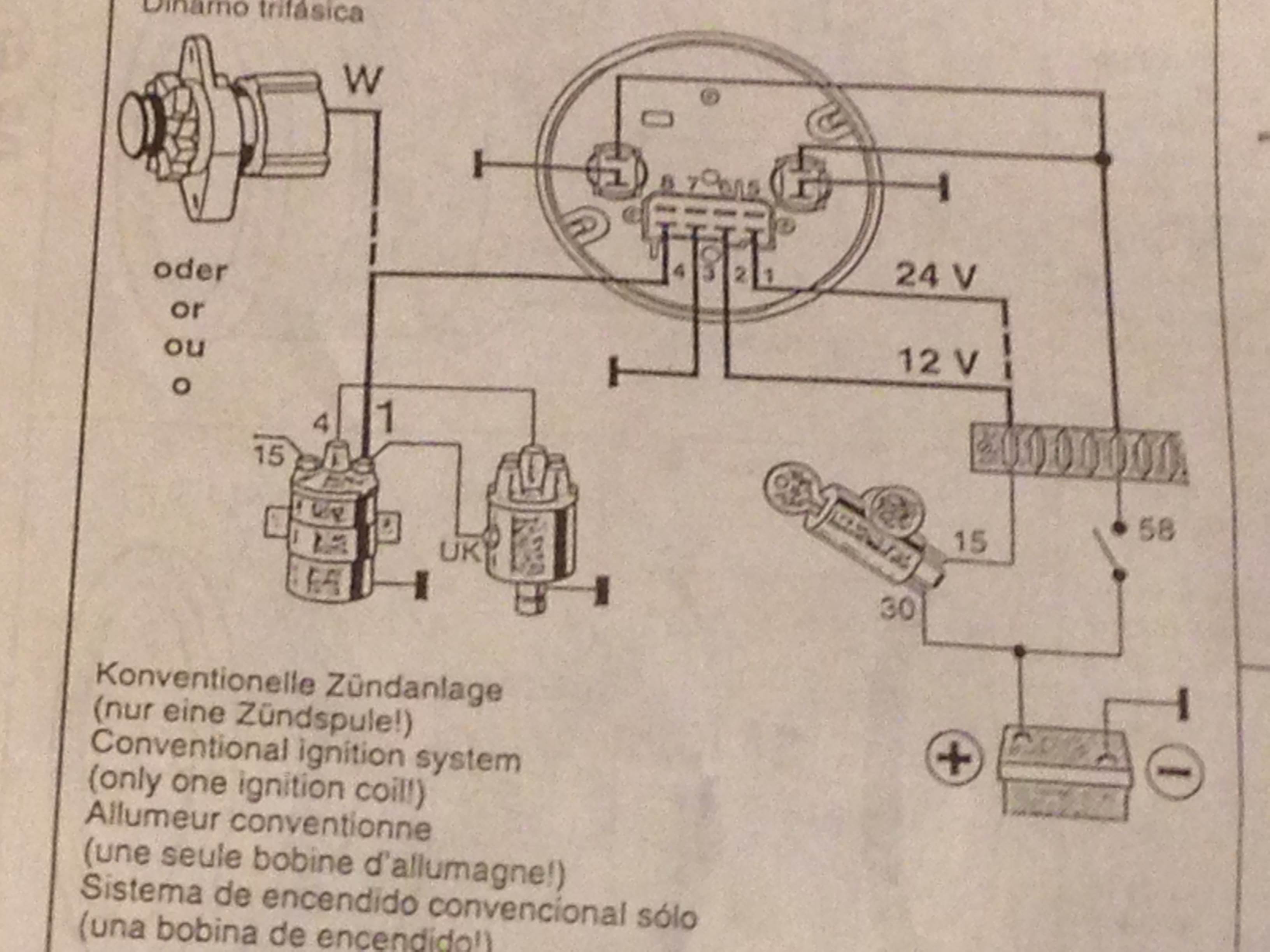

HG I would like to do the same thing to my Bukh DV 24. Oil and temp gauges; and a tacho. Is it difficult to fit a tacho?

Andy

To be honest Il not sure how accurate it will be as it takes it impulses off the Alternator I will have a read on the instruction sheet and let you know.

I use a alternator off a Holden 80 amp and also the pulley that came with it this was slightly smaller diameter than the original pulley .

Ill have a read after dinner and get back to you

At the worst it will fill a hole in the stern of the boat that will look better with a tacho in it ![]()

Boy of boy not much English on the instructions on this bad boy and the print is small and fine

2 = 12 volts 3 = earth 4 = W off the alternator

That hole between 2 and 3 I think is a fine adjuster.

I have not use one for many years but there is a mechanical tacho that you can hold onto the flywheel and it spins up to the engine RPM and you read off the RPM and verify or adjust VDO tacho to match it and its done but it may only need checking to verify the VDO tacho to you engine

![]()

cisco said..

Well I put some paint on 1 side of the boat.........

Damn!!! That will be a fast trimaran when you add the pontoons and rig to it. ![]()

Cisco! You're normaly spot on with most things boating but the greenie above is the starboard hull of a cat. Not a tri.

Found it unloved in a paddock a few years back........

cisco said..

Damn!!! That will be a fast trimaran when you add the pontoons and rig to it. ![]()

Cisco! You're normaly spot on with most things boating but the greenie above is the starboard hull of a cat. Not a tri.

Found it unloved in a paddock a few years back........

Methinks that Cisco knew that and was trying to be funny

Cisco! You're normaly spot on with most things boating but the greenie above is the starboard hull of a cat. Not a tri.

Found it unloved in a paddock a few years back........

Even better!! Two trimarans out of one catamaran. ![]() Just kidding.

Just kidding.

What is the design and length again?? It looks like it will be a rocket when you are done.![]()

yes, looks Mad Maxish/Raider with stealthy extended 'don't piss me off sterns'.

If original owner saw it now.

Green is definitely the right color for it.

yes, looks Mad Maxish/Raider with stealthy extended 'don't piss me off sterns'.

If original owner saw it now.

Green is definitely the right color for it.

Tis an early Grainger and its heavily modified.

Reverse rake bows, Stern extension, New Daggerboards and cases transferred to opposite side of hull, Beam connections modified to bolt on rather than glassed on tubes, Redesigned cockpits (big job), New beams, Dynex rigging for mast, New sails, Side tinted window recessed rather than just attatched (big job), Lungs removed and purged of all dust and toxins and replaced, Redesigned interior- Yes you can cruise in it, Full standing headroom....................

Its now 40 ft long which is a good length for speed to which I am sadly addicted!

We'll done hangtime can't wait to see it in the water. Hanging a hull on a reach 40 ft would be real nice![]()

There was recently a GBE for sale, I think either Gumtree or Boatsales that was the same colour .... not yours by chance and you are using up left over paint?

Looks a lot like the strip planked red cedar cat with a wing mast that was built at Shoalhaven Heads a few years ago

Looks a lot like the strip planked red cedar cat with a wing mast that was built at Shoalhaven Heads a few years ago

Was told that only two were built from the original plans and the other was built down that way . Would love to see a photo of it if its still around.

The multi nats would be awesome to be competing in but someone told me its cold down there?

![]()

Added a few electrical items and removed some of the temp stuff Id fitted still a bit to do in there but its a start.

Permanently wired in a my 4 led strips under the settee's will make a wooden shade to direct the light towards the floor also fitted two dimmers one for each side

Oiled the stern wood work Ill post a photo tomorrow after the second coat

Looks a lot like the strip planked red cedar cat with a wing mast that was built at Shoalhaven Heads a few years ago

Was told that only two were built from the original plans and the other was built down that way . Would love to see a photo of it if its still around.

The multi nats would be awesome to be competing in but someone told me its cold down there?

![]()

Sorry don't have any photos. Lovely boat, I had a look inside during the final stages of construction. The wing mast was a problem during Westerly gales. It rotated freely but still generated enormous drive even when the soft part was down. The owner reckoned he could not get near her to board her when it was blowing. The mast was of plywood construction with a chord of about 3 feet at the base.

It is a fair while ago now and I'm fairly sure she went North when sold.

Damn!!! That will be a fast trimaran when you add the pontoons and rig to it. ![]()

Ok so Cisco was fishing for a bite?!

Doh

We are getting a bit of rain lately which is welcome and overdue but it does slow me down a bit getting work done on the boat.

The engine has been stripped of external bits, alternator, starter motor, water pump, hoses, fuel lines etc.

I then scraped the old paint off and wire brushed the rusty areas of the engine. A good degreasing followed as preparation for a coat of Kill Rust Rust Eeter. It is phosphoric acid based and therefore turns the cured rust black. The acid in this product is carried in a plastic medium which when cured forms an impervious coating.

The engine after rust treatment.

The red on the front of the engine is International PA 10 etch primer and is on the governor housing which is alloy. PA 10 is probably the best etch primer for aluminium.

The other red parts are in Kill Rust delicious red enamel which I chose to highlight the areas for regular maintenance.

I am not really fussed on flexible engine mounts. They make it almost impossible to maintain good engine alignment. I have the stbd rear mount out and have measured it's dimensions so I can fabricate solid engine mounts. They will consist of a quarter inch base plate drilled for the coach screws into the beds with a length of 5/8 inch UNF high tensile threaded rod in the middle with a welded nut on the upper and lower sides of the base plate.

The base plate will sit on a hard plastic slab 30 to 40 mm thick, recessed for the nut on the underside of the base plate. These mounts will allow engine alignments to be done the same way as now by adjusting nuts on the thread rather than using shims.

I have fairly good access to my engine as you can see. Unfortunately though there is not enough room on the exhaust side to get the manifold off nor is there enough room above the rear of the engine to remove the cylinder head with out unmounting the engine from the beds. For this reason I am doing everything possible maintenance wise to the engine short of taking the head off.

The injectors have been reconditioned and one nozzle replaced with new. I am leaving the injector pump alone for the time being. If the engine runs well and smoothly when I get it going again, I will be happy enough with that. Based on what I know of the yacht's history of 32 years, I am punting that the engine will only have about 6,000 hours on it. These Yanmar 2QM 15s are hardy little engines and should be good for 10,000 hours before a major rebuild is needed.

These shots are of the engine after painting with Kill Rust Heavy Duty Primer and views of my cockpit locker/lazarette area. The Lotus carries almost her full beam right to the transom. I have taken the 100 litre bladder water tank from under the fwd Vee berth as she was sitting in the water with her head down. That improved her a bit but she still has her head down. Somehow I need to get more weight into the stern.

The partition to the left of the fuel tank is where I can store up to four 20 litre fuel drums and they with the 50 litre fuel tank giving me a fuel capacity of 130 litres. This gives me a motoring range of about 360 miles.

That spikey looking thing sticking up just behind the rib is the glass encased root of the "P" bracket. Just behind that is where I store my spare Danforth anchor, chain and warp. I secure it with a piece of lashing from the end of the shank to around the cockpit drain with a slip knot for rapid deployment.

Looking nice Cisco

Like mine you still have to be a contortionist. By the end of the day you have a few saw joints and a couple of bruises for your effort

Well I scrubbed the cockpit and the starboard side deck didnt get time to do a second coat of Watson wood oil on the stern timber. If there is enough sun tomorrow Ill sand down the timber on the startboard side and wash with some Watson wood cleaner ready for the next day that the sun shines down here . Cisco you know what I have to put up with as your rained in right now.

South Ace was right the Watson's wood oil works well and no problem to use. I just use clear wood oil no colour

I had a few sikkens stains around the bow when I tried to poil her up many months ago while on the swing mooring on a rough day so I scrubbed them off .

I bought a speedseal pump conversion unfortunately it wont fit the 6 bolt pump flange thought it may thats why I took a chance,

So Ill put that on the back burner and find out a bit more and see if I can source a 4 bolt pump housing

I thought I might be able to drill and tap new holes in the pump housing but the speedseal doe not match up with the speed seal.

So Ill wait and get back to it .

Mounted my dimmers on each side of the settee these can be turned off there as well. But with a peice of wood used as a shade and deflecting light towards the floor should be good.I set them on a 45 degree angle as they are so you don't really get any light in your eyes while sitting on the opposite side settee. Another reason for the wood shade is making sure there is no sharp endes to cut your self on while walking past it is flush with what wood is there but to make sure ill do it.

I had a slack attack after this and went home for a power nap thinking id go back down the couch was far to comfortable and it never happened.![]()

Well I scrubbed the cockpit and the starboard side deck

Hi HG

It is looking very nice

Have you considered fitting a intermediate horizontal bar to your pushpit

Regards Don

Well I scrubbed the cockpit and the starboard side deck

Hi HG

It is looking very nice

Have you considered fitting a intermediate horizontal bar to your pushpit

Regards Don

Yes Donk a boiler maker at work will be doing some stainless on" SV Driftwood" over the next 12 months and that one of the thing thats needed .

Theres a boat in Tassy with a nice rail set up here a photo Ill probably to some thing very similar.

As I get older and stiffer I felt that this may be a solution as you can see it has a nice fold down ladder both sides plus my boat should real have a second rail to make it safe.

I hope also to find a wind vane some time in the future

Hi HG

That bar work looks nice

How far forward would you go as it looks like the one in the photo stops just forward of the ladder

It would make it a lot easier and safer to go forward in bad weather and to board from a tender

Regards Don

Hi HG

That bar work looks nice

How far forward would you go as it looks like the one in the photo stops just forward of the ladder

It would make it a lot easier and safer to go forward in bad weather and to board from a tender

Regards Don

just the same Donk no further. I have not looked hard yet . I hope it does not make it hard to move forward with that ladder arrangement Ill check it out tomorrow.

When I had the boat surveyed it was mentioned about not having a second rail

Hi HG

That bar work looks nice

How far forward would you go as it looks like the one in the photo stops just forward of the ladder

It would make it a lot easier and safer to go forward in bad weather and to board from a tender

Regards Don

you could even place a piece of ply on the ladder if you were in a marine as a boarding platform for old ladies looking for a good time from an old fella ![]()

My hands as sore as from working on the boat so much there cracked badly . Might have to take it easy next week

HG I would like to do the same thing to my Bukh DV 24. Oil and temp gauges; and a tacho. Is it difficult to fit a tacho?

Andy

To be honest Il not sure how accurate it will be as it takes it impulses off the Alternator I will have a read on the instruction sheet and let you know.

I use a alternator off a Holden 80 amp and also the pulley that came with it this was slightly smaller diameter than the original pulley .

Ill have a read after dinner and get back to you

At the worst it will fill a hole in the stern of the boat that will look better with a tacho in it ![]()

Boy of boy not much English on the instructions on this bad boy and the print is small and fine

2 = 12 volts 3 = earth 4 = W off the alternator

That hole between 2 and 3 I think is a fine adjuster.

I have not use one for many years but there is a mechanical tacho that you can hold onto the flywheel and it spins up to the engine RPM and you read off the RPM and verify or adjust VDO tacho to match it and its done but it may only need checking to verify the VDO tacho to you engine

![]()

Thanks for the info HG did you try it out yet?

Still making permanent wiring for the engine Andy. I have the boat parked up in a marina for a few months so I'm in no real hurry. May test run it next weekend for 30 seconds with out a water pump to test every thing . I will be pulling the fuel tank out and modifying it for the sender unit and replace all the hosing, fuel filter.

Plus I will see what I can do with the water pump as well Ill replace all the seals in the pump. also tappets to do and repaint the tappet cover probably replace the decompression lever seals in that as well over the next couple of weeks and a new tappet cover gasket.

Not a bad day today so it sanding the starboard side deck timber while theres a break in the weather